Hi Guys,

Has anyone tried carbon fiber foil boxes? Armstrong says they have a proprietary carbon foil box and rails.

Looks like a more stiff foil box will make all set up stiffer

hard to beat these - light and long. they also have shorter ones.

I think Takoon is also using proprietary carbon tracks.

For DIY projects i have bought a couple carbon track sets from these guys:

Still have not mounted them but they feel very good and well made.

They weigh 280grams, 14 inches long.

For comparison to FRP tracks:

Futures 10in weigh 256grams

Chinook 15in are 370grams

I think weight won’t be a big issue. My concern is how much we gain with a stiff foil box

IMHO a carbon foil box by itself is not going to be significantly stiffer than a good quality FRP box.

Stiffness is going to depend way more on how those tracks are attached to the board’s composite structure (lam and foam).

Boxes connected to deck by carbon fiber and bottom hull skin reinforced in a way that takes compression loads (specially in front of boxes) well is what will give you a stiff ,direct feel and make it durable.

You can do that with FRP or carbon.

Carbon tracks mostly give a weight advantage and a better adhesion to the lam than plastic, less chance of delam and water ingress.

Cons of carbon might be impact brittleness and low abrasion resistance to the foil box slider nuts, we will see how they work out with time.

Hi Dontsink, thanks for reply

Agree we need a good foil box anchoring like a divinycell plank or stringers under the boxes.

Low abrasion should be an issue

The box is just a thing that holds the nuts. The structure comes from the carbon that is sandwiched between the box and the plate and the structure connecting the track to the deck. I use the chinook boxes, mount them in a block of d cell foam, wrap that whole assembly in carbon before I put it in the rest of the board so I have good foam and carbon connecting those boxes to everting else. Even with the crappy futures boxes or other off brand Chinesium boxes I’ve almost never seen a box fail. It’s always the surrounding foam/glass/carbon

Makes sense. I use the same way. If we have carbon over the boxes and under the d cell foam, it will be very stiff

Thanks!

Hi I’m making my own integrated prepreg carbon fibre track boxes. They are like small Tuttle boxes and laminate in through the bottom and deck of the board so don’t need heavy foam blocks putting in the board.

Sick!!

Can you share the process ?

I did something like this in the early days. Id take a chinook box, glue on a HD foam extension to the top to make it 5” tall and wrap that in carbon to bond the deck to the bottom. It was ok, I don’t think it’s a replacement for running foam and carbon all the way to under the front foot. Id say doing both would be ideal.

honestly I see all these carbon track box posts and I’m really not feeling it. Chinook boxes are great, tough as nails, and I don’t think they are the weak link in the stiffness equation. I exclusively use an impact driver for my track hardware and it’s fine. I guess they’re a little heavy but I feel like a hand laid Carbon box With a big weight Advantage would be more fragile than injection molded glass reinforced plastic.

Totally agree that GF/plastic boxes make a lot more sense. Epoxy and carbon have a significantly higher specific gravity than polyamide or ABS with glass-fill (which is usually very low% GF). So the carbon box of similar dimensions is going to be heavier and not really offer any advantage (can look cool though). The carbon box will always need a certain level of bulk similar to the plastic box to accommodate for the nut track. Also, the carbon box will take more labor hours and material $ to build. I’ve built a lot of fin boxes over the years (>100,000s), and GF/plastic wins. Carbon/epoxy does make a really fun awesome looking home project.

I have made my own carbon boxes in the last 4 boards.Working fine so far.

Just 30cm long…but you do not need more if you place the boxes correctly.Those 15inch bockes are IMHO a sign of how badly the “industry” solves problems.

FOILBox Position:

Mark the Center of Buoyancy, measure 30.5cm towards tail and that is the middle of your foil box position.

Center of Buoyancy is Center of Gravity of shaped blank,no routs or inserts installed,just foam.

(My) STRAP POSITION:

FrontFoot BackScrew: CB+15.5 (FrontFoot FrontScrew 50* 18.5cm)

BackFoot FrontScrew: CB-20 (BackFoot BackScrew 17.4cm)

Why carbon?

First of all ,a challenge ![]()

Impact resistance of carbon may be worse (brittle) but rigidity and bonding to lam is way better than plastic.Also cheaper.

I buy these pieces from AliXpress DZQ CARBON FIBER STORE

Carbon Flat Plate 200x300x 5mm

2 Square Carbon Tubes 20x20x18(inner) x 500mm

From ClipCarbono.com Square Carbon Tubes Stringer 8x8x7(inner) x 1000mm

I also use round carbon tubes 15mm exterior 13mm interior diameter as pillars to connect to deck ( 4 each box)

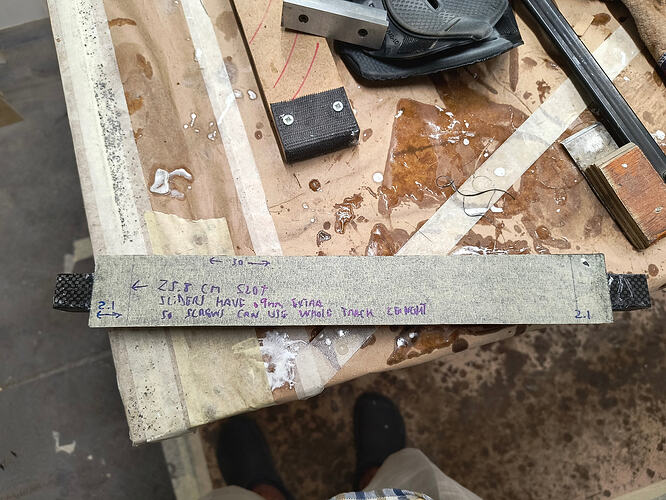

I cut the plate to 30cm x 4cm strips so you can build 4 boxes with the material above.

Square carbon tube is epoxied to plate after sanding,i put a 50gram strip of glass between as filler but any thickened epoxy will do.

With a jig i router the slot.

Seal both ends so it is watertight.

Boxes are heavier than plastic but they will not use any PVC foam block,they are a solid carbon structure for all main loads.They have a huge bonding surface to lam and it is epoxy to epoxy.

Router XPS and Gorilla Glue tubes and boxes.Pillar tubes must be touching boxes or they will do nothing,i set them first but many ways to do this .

I VacBag and add weight to keep from boxes lifting.

Bottom lam is pretty standard with carbon patches,sizes adapted to board:

100gr Box size patch.

160gr 40x55

160gr 45x65

100gr Standing area 80cm x 1m Full Overlap

152gr Carbon Innegra Final Bottom layer

very cool information, than you for sharing! I am somewhat surprised you don’t glue the stringers directly to the box before installing into the blank

I can’t really argue with this kind of input. It make me rethink building my own carbon boxes.

I have two questions :

- If I understand correctly, saying that Epoxy/Carbon have higher specific gravity just mean that they are more dense (weight/volume) compare to ABS/Glass-fill ?

- In what type of work have you built that crazy amount of fin boxes? Working for Futures ?

I did that on a previous board.

But it creates a lot of alignment,routing and installation problems.

The role of the stringers is more in compression than longitudinal bending the way i visualize the loads.

They are very well bonded to the bottom lam so a frail bonding to the box itself is not as important as it might seem intuitively…i think ![]()

BTW the installed boxes weight (boxes ,pillars and stringers plus gorilla glue came out at 320grams.