I miss the old forum days (other forums from years past) when people would post up big project dumps in a huge thread. I guess people aren’t doing that so much any more, but I thought it would be fun to try out here.

This entire foiling adventure started out with tuttle for many of us - I personally stuck with GoFoil tuttle mast long after it was clear that the adjustability of plates would win the day. Eventually I gave it up and went to plate masts, but almost every session since the last 5 years, my mind wanders to wondering if that plate drag really matters. I decided to find out once and for all.

I figure there are only so many more places for innovation in foiling, we’ve squeezed a ton of efficiency out of the board, foils, and especially masts - getting rid of plate drag seems like a low hanging fruit for improvement. Not only for takeoffs and touchdowns, but also for stiffness and weight. I figure a tuttle mast can be stiffer than a plate mast because the carbon continues straight into the board, the tuttle makes a more rigid connection to the board, and my overbuilt prototype tuttle box is already lighter than a pair of tracks set in 6lb PVC foam.

Though I’ve been turning it over in my head for years, this particular project began 5 months ago on and off weekends and evenings whenever I had the energy and focus and push it forward.

I started with designing and procuring the tooling for both the adjustable tuttle box as well as the potting tool for the mast head fitting and the drill jig for the mast. Here we are ready to layup the foilbox.

After the carbon part is laid up, I used 3D printed guide to glue on carbon tubes to support the force of the screws going to the deck. A simple wood form is for the 4lb pour foam.

And finally the trimmed and ready foilbox. The pour foam didn’t work so great at the top, but it will be trimmed flush to the deck after install so no big deal.

Next up, the tuttle mast modifications. I happen to possess two identical AFS UHM carbon masts, so I decided to modify one of them. I’ll be able to directly compare the plate mast to the tuttle with exactly the same board/foil/conditions. I didn’t take any photos of the circular saw cutting off the sides of the baseplate because I was too nervous the saw would kick back and get me. That part was dicey. But generally I trimmed off the baseplate and ground back the base of the mast for potting.

The two-part potting tool worked perfectly with chopped carbon/epoxy to fill out the shape.

Finally the 3D printed drill jig with drill bushings to make the holes in the right places. The second set of holes allows the mast to be indexed to half positions along the hole pattern in the foilbox.

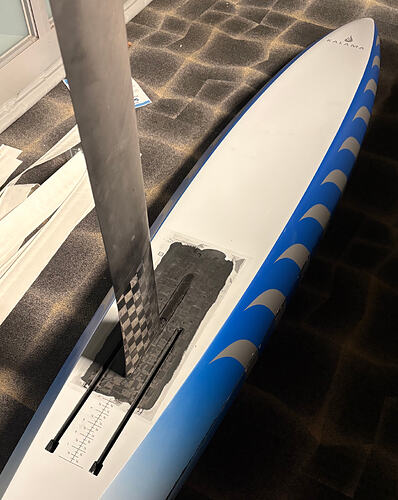

And now to install the foil box in my downwind board. I lasercut a router template to get the cutout in the bottom and the deck, then used a hand-saw the rest of the way through. Gorilla Glue filled any gaps, though it was a nice tight fit already anyway. Yeah, I want the mast further forward, but I placed the box so the furthest back tuttle position matches the plate mast furthest forward position.

I hand laminated carbon for the bottom and the deck. Peel ply helped limit excess resin

Ready for hot coat on the bottom. The top gets washers and deck pad.

And I finished a few nights ago. Got the setup out for a SUPFoil surf session for the first time this morning and everything worked perfectly. Hopefully I’ll have good weather for a couple of direct A to B tuttle to plate test sessions this weekend. Stoked!