Was thinking of making my own foil board like lanceisoutside on youtube. He does standard fiberglass lamination like for surfboards. The board he made is 3" (EDIT: I meant 6") thick from insulation foam. Seems intriguing and like the idea of tons of volume to get into the wave early. Is it a fact that board thickness does or doesn’t affect the ride or feel while up and foiling on a wave? Pumping etc?

Here he is shaping the board https://www.youtube.com/watch?v=X496qvFC2bU&t=352s

Here he is riding the board https://www.youtube.com/watch?v=3YdIeA2c7oI&t=154s

There is no one design aspect that defines a “good” board, but rather the interplay of multiple concepts. Often a concept that makes a lot of sense for one person or one type of wave condition, doesn’t actually work well for most. I’d say that of Lance’s board. But hey, he made a working foil board and can refine the design until majek happens. Or perhaps the magic already did in the joy of shaping his own.

If you’re on facebook theres an excellent board & foil builders page with all the resources you would need

Good points . It appears his boards achieve what he wants it todo. I think that would be the case for alot of people considering how much foil boards cost new. I love the idea of a crossover board that seems to just work but doesnt break the bank. A board using surfboard tech is quite a bit cheaper than cf vacuum bagged $1500 boards. Cheaper also means more room to iterate thru deaigns. But I get it some people just want to buy a good product, others want to make their own. But in general does a thick board negitively affect a foil board in the same way it would for a surfboard? Loss of sensitivity or control? Of course Im just speaking in general terms. One could argue for certain instances even a thick surfboard can be better in few instances.

I love diy and for most people an easy to use cheaper board would really lower the barrier to entry in this sport.

Do you happen to have the link to that reaource on fb? I would really appreciate it.

IMHO a thicker board should feel the same as a longer mast once up on foil.

Unless the box is badly constructed and flexes.

Facebook boardbuilding group:

I agree. In normal surfing the thickness of a board affects a lot considering rail shape and also the “distance from the water to the top of the board”. The thicker the board, the more lever you have over the point in contact with the water, which gives you different feelings on the handling of the board.

In prone foiling, a 1 or 2cm difference on the thickness of the board doesn’t seem like it’s going to affect significantly considering the 50cm above the water you already are (75 cm above the foil itself)

I have found generally to be the case that thicker boards feel worse, thicker boards have less direct feeling.

I don’t think this is related to the physics of distance from foil, but rather related to construction. I think this is due to the foam compressing.

My understanding is that the carbon/foam sandwich, and the tube shape of the rails all combine to create a rigid connection between foil and feet,and 6" of foam just gives you more compression (someone validate from the board building group?).

I’ve only ever preferred thinner boards. I have not run the tests of an otherwise equivalent board only varying thickness, but I’d bet that most could feel and say that 6" feels worse than 2".

I would absolutely refuse to that board in the video just based on how it looks like it feels. Presuming the mast is stiff, then it has all the vague imprecise feelings I associate with a thick board!

You’d be surprised. 2cm is maybe, and 5cm is absolutely going to be noticeable (5cm=2inches,the range we are talking)

In his board construction he does add several vertical stringers under the deck between the foil tracks too. For a 3" (EDIT: I meant 6") thick board this would really stiffen up the construction. I would think that would be about as stiff as most moderately skilled foilers could notice. Also a stringer reinforced board should be much stiffer flexwise than a 1.5" board made with cf due to the distanceapart from the skins I would think.

Now for an advanced highly skilled foiler who is really putting their board thru its paces I would say just go for the best construction and do cf vacuum bag and be precise on volume and dims etc.

EDIT: Sorry I meant 6" thick board not 3"…

Just to check, his board looks like 6" not 3"? 3" is normal for prone board, that board looks as thick as a DW board which often are that range.

I made a DW board, put a lot of effort into making it strong and thin with reinforcements, drop deck. It worked well. 4.8" range, but still 2" thicker than my prone board and I feel like the combination of the mass dampening of the big board and the thickness of the board make it feel less precise.

What I don’t know if it’s 90% the weight, and 10% the thickness. @Beasho probably will say it is all the weight, and thickness doesn’t matter, and has likely done the tests to prove it ![]()

I build all my own boards and lean on the thick side because I like the buoyancy and speed on the water. Just built a 6’0x17x5 wing/parawing/prone downwind board and I love it. The narrowness makes it great for sharp carving turns. I tend to believe that a thick board just adds to the mast. But take that with a grain of salt - none of my boards are less than 4” thick except my wake foil boards.

That group has a wealth of information as I build my first mid-length. I particularly like the Jimmy Lewis videos where he shares how he builds lightweight, strong boards without vacuum bagging.

Sweet thx Im gonna go watch jimmys videos.

What I recall from learning about composites in school, increasing core thickness increases the stiffness of the structure. If the core is compressing that’s an issue with the skin not being stiff enough to spread the load.

Matt my apologies, your righ 6" thick not 3" thick. too many numbers running in my head. And then thinking relative to surfboards etc…

Yes thats my understanding too. And with several added stringers below the foot and above the foil box it should be really stiff.

Many of us are conncting deck and boxes with carbon instead of PVC foam.

This concept was started by Dwight Fisher who made Foil Surf Machines boards.

Oh cool where do you get the carbon tubes? Is this stuff documented on the FB builders group? I’m still trying to join (pending approval).

I am always changing things on every board, goofing around is part of the fun

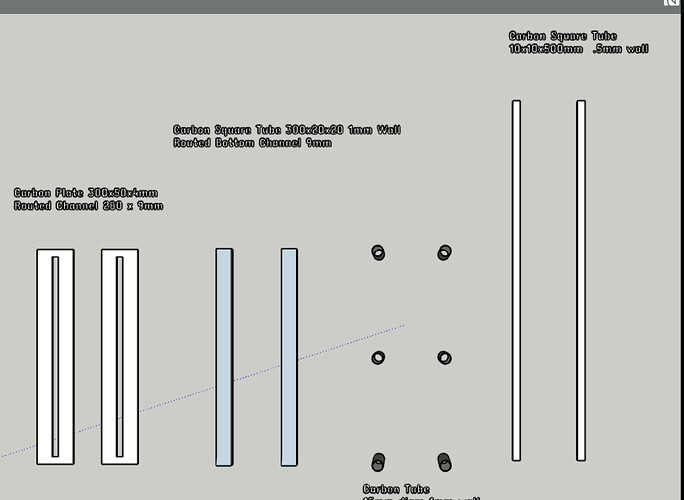

…on this one i used 15mm diameter tubes with 1mm wall as pillars.

The partial stringers are square tubes 10x10mm 0.5mm thickness.They prevent compression of bottom lam in front of boxes.

The idea is to not rely on foam,which “fatigues” quickly,to take the loads.Carbon can take lots of cycles if laid in proper form (flat laid is good for traction , tubes are good for compression ).

You can buy carbon parts in aliexpress (cheapest) or google carbon tubes and find a local vendor.

Plenty foilbox designs in FB, it is a bit chaotic and i would prefer a forum but…