I’ve only ridden the 72 sorry! For what it’s worth the 72 measures identical to axis 75 (the 72 is to the start of the ‘doodad’ section of mast). You folk probably already knew that…

Sorry I maybe wasn’t clear, I was asking about your experience with stability and control, specifically this line, taken somewhat without the preamble context

Decreased stability in turbulent waters and tip breaches.

Thanks yes that helps

The actual thought is:

I am wondering if the feeling you describe comes down to the less stable nature of a shorter chord. Seems likely not the case, but something to consider.

Ia that a custom mast from AFS you’re getting next week? I don’t see those measurements on anything on their website

I guess this is the 75

I believe they are also working on a skinnier mast (less chord and thickness) ; at least around 85 cm. The 85 is already a super super good mast.

With such a low chord, you can miss a bit of precision when pumping.

The 80 seems to me more recommended with larger Foil (such as the Enduro or the Ultra)

I have heard some complaints from (potentially bias) axis HM users that their friends with NLv2 have had to shim their axis adaptor to get a good fit. Has anyone got photos examples of the alu tape used for such purpose? Id like to make sure I’ve got the connection as stiff as possible.

I am a hobbyist hydrofoil gear builder with an engineering background, currently working on designing and building a new mast, and stumbled on this old thread. It has some great info that is very useful!

It’s a challenge to filter this discussion. It seems there are academics who understand theory but struggle to design a really good mast, and pragmatists who just tried a lot of things and found what works best, without really understanding why. I have worked on this problem for some time now, maybe I can share what I learned.

I’m assuming most designers here use XFoil/Xflr5 for basic CFD analysis when discussing foil/mast sections.

In this thread there is a lot about the drag coefficient: Cd. The drag force of a mast increases with the drag coefficient, chord (“wetted area”), and velocity squared. Thickness is not part of the formula, thickness is reflected in the drag coefficient. Thinner sections can have a lower drag coefficient, but this is certainly not a given and very dependent on speed. The thick Axis 19mm section has a very low drag coefficient.

Then there is talk about stiffness: bending and torsional stiffness. Stiffness scales with the 4th power of size, assuming it is solid. So if you scale thickness from 16mm to 15mm - also scaling the chord, it becomes (15/16)^4 = 77% as stiff, 23% less. It’s a bit more complex when the section is not solid, but as a first approximation this will hold.

Then there is ventilation. This is the hardest part, it seems hard to approach from a theory perspective so the pragmatists have the best insights. Thicker sections and blunt leading edges are problematic. Also scratches and poor surface finish. But why?

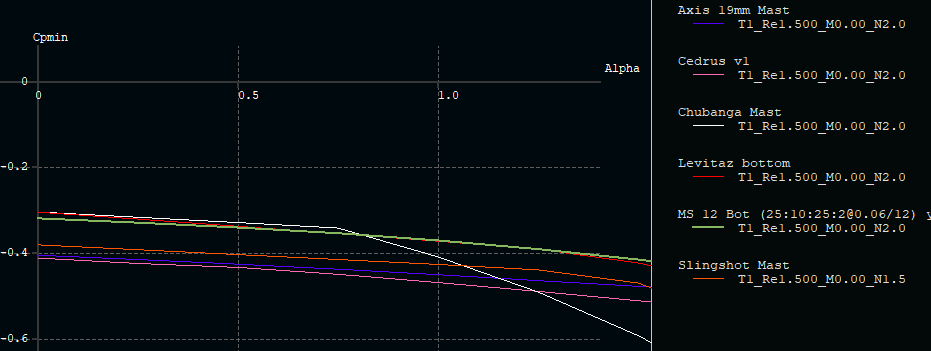

@ProjectCedrus mentions a relation between ventilation and separation angle, which I do not believe is relevant here. I think for ventilation we should look at the Cpmin graph. A mast will usually work at very low angles of attack, mostly under 1 degree. Thicker and blunter masts like the Axis 19mm and Cedrus v1 have Cpmin around -0.4 at that angle. Racing masts like the Chubanga are near -0.3. This translates to less negative pressure around the mast. A small wave hitting the mast sideways can create a small vortex behind the mast, low pressure can suck that vortex down and the mast will ventilate. So in order to design a ventilation resistant mast, I think one needs to select a section that has good values for Cpmin at angles between zero and 1 or 2 degrees AoA. I’m not sure about the exact number, it may depend on discipline and rider style. Anyway: thin sections with a sharper leading edge have better Cpmin values at small AoA, I think that explains ventilation from theory.

Finally, this thread does not really mention pitching moment Cm. In my foil section collection, I noticed that all fast masts use sections that have very stable and low pitching moments at small AoA for the whole speed range. So it is probably essential for a mast to have a very stable pitching (Cm) graph. If Cm changes too much, it probably will feel directionally unreliable. If the pitching moment is positive, unstable wobbling may result.

I think the latter two requirements are why thinner sections are “better”. If drag was the only thing relevant, a scaled-down, 10 cm wide, 15 mm thick version of the Axis 19 mm mast would win races. But tracking behavior and ventilation resistance seem to be as important as drag.

For my own mast design I created a foil section optimizer program that calculates all these properties at different speeds and angles, and weighs them against each other, normalizing for stiffness. I can play with these relative weights and see what optimal section comes out. This program showed me that just optimizing Cd results in very thick sections, increasing the importance of Cm leads to thin sections, while Cpmin importance depends a bit on angles, but optimizing for small angles also promotes thinner sections.

Let me know if this is useful.

Maarten

Thanks for putting in all the work on this! I’m just trying to summarize here but am I understanding your thoughts correctly?

-

Thinner with narrow leading edges to beat ventilation.

-

Deeper chord for stability and to allow the narrow (not so blunt) leading edge.

Would love to see some pics of your builds!

Here a mast comes from the vacuum infusion mold. This mast is good, but I’m hoping to improve it.

Here is a picture of a complete set. This front wing has a highly cambered section, I dialed this back a bit in my latest front wing designs.

Wow this looks awesome. I’m not sure what most DIY foil builds come out looking like but this is great. How’s it ride? Tail looks wild, did it stay stiff with that shape and thin chord?

The tail is not that thin, it’s very pitch-stable and also has directional stability which I like. Better foilers than me have called it “boring”. It’s great for winging, less so for pumping.

After the mast project, I’ll dive back into stabilizers.

Very cool. Keep it up, looks great. Do you have current mast dims and what you intend to change and why that you could share right now?

I computed three optimized sections for my mast, optimized/normalized against stiffness:

- The bottom part is mostly optimized for drag and stability (Cm and Cd) at high speeds and low AoA.

- The middle part is optimized with more weight toward ventilation (Cpmin and Cd) at high speeds and slightly wider AoA.

- The top part is optimized for drag and ventilation (Cd and Cpmin) at lower speeds, as it is in the air at high speed.

I averaged for multiple values of n_crit, which determines the transition point and is dependent on turbulence and particles in the water. I think it’s lower for the middle and top sections (near the water surface).

The bottom section came out at 12.4% thickness, and is on par with 11.5% thick racing masts in ventilation and stability and has lower drag.

The center section is 12.6% thickness, the top is 13.3%.

I want to use wide span front wings and want it to be stiff. I’m aiming for 15.5 mm thickness, so the chord was set at 124 mm. The mast tapers out towards the top.

How this mast works on the water will depend on the balance between properties and numbers that I put into this optimization. I know from my front wings that finding the right balance is hard: it took many attempts and I made many wings that work well but lack real magic, but for front wings I now know what numbers to use. This is the first mast I’m designing this way so I am really not sure how it is going to work: I’ll have to build it to find out.

I’m open to sharing high-res dat files, but I want to learn something and get feedback in return. I’d also love to hear from others doing this sort of optimization (@KDW ?).

I’m lost on what the percentages are referencing? I bet there are people in the foil building group that would be into sharing info with you.

That is the thickness as a percentage of chord. If the mast is 124 mm wide and uses a 12.4% thickness section, it is 124 x 0.124 = 15.376 mm thick

I hope nolimitz v3 is a thing. I think I heard on a podcast that they are presumed to not be operating anymore.

NoLimitz is over. New ownership decided foils aren’t worth their time and they are only doing the big aerospace accounts now.

Something of a pity, I’ve been riding the v2 78cm on code and it works really well

Same. I’ve AFS, F-One and Armstrong adapters for my 78cm. Its been great to swap gear around for testing.

Lately its been my Foil Drive mast and makes things super convenient. But the thought of losing a plane due to the adapter coming off is starting to worry me.

Very sad. Where am I going to find 1.3kg 85cm mast anymore?